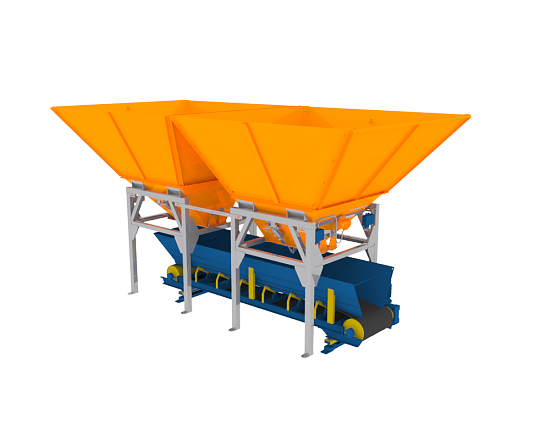

Devices features

Batching complexes have some fundamental features. These include:

- The presence of pneumatic controls and gate valves in the bin. This allows controlling the material feed rate and ensure the proper accuracy.

- Unloading occurs using gates. They open in electrical mode using the pneumatic cylinders.

- The control is carried out based on the microprocessor system.

- To ensure accurate weighing and batching, modern strain sensors are used.

- The bins are mounted on a special frame. This allows their fast dismantling and transportation.

Our Advantages

We work with big and medium-size companies of Russia, Kazakhstan, Ukraine, Belarus and other countries and always fulfill our obligations in time.

Shipping, customs control, documentation - we will advise you on all matters, as well as help you set up and configure the equipment

We have our own logistics system for delivery of products (vehicles, transport companies)

Due to our own production, our prices are lower than the market averages by 15-50%