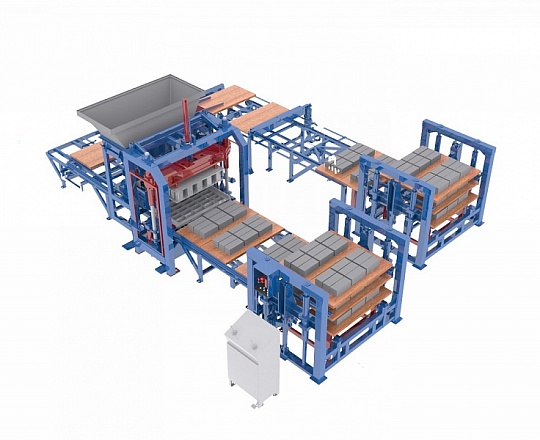

1. Work in automatic mode;

2. The support shelves, when hoisting, approach the pallets in parallel, touch them without shift. The pallets are hoisted and lowered smoothly, without rocking the upper rows, which allows avoiding the appearance of cracks and destructions on the freshly molded products. This is provided structurally, due to the use of four columns, brackets with guides of increased length and a rigid synchronizer connecting the left and right sides.

3. The hoist and the lowering device are equipped with a separate pumping unit. At the same time, the movement speed of the working bodies and the complex capacity are maintained, which will not be ensured by connecting the hoist from the press pumping station.

4. The ability to adjust the hoisting height depending on the product height to reduce the cycle time;

5. Large load capacity, high operation speed;

6. The modular principle allows retrofitting the initial minimum equipment with a bundler and a lowering device for automatic unloading of pallets with finished products.

7. Versatility - the product can work as part of different complexes;

8. If necessary, the hoist can be completed to the lowering device and vice versa;

9. It is provided the hoist (lowering device) disassembly and bringing it into the transport position, which allows reducing the volume occupied during transportation by 2.5 times;

10. The length of the pallet feed module, on which the pallets come out of the press, allows placing three pallets with finished products. The installation of the second layer module will not interfere with the work and will not worsen the visual quality control of the resulting products. Spacers can be placed on 2 pallets at once, which speeds up the process and increases capacity;

11. There is no need to prepare a place to install a stack with pallets in the steaming chamber. The hoist design simplifies the process. Before driving up to the hoist, the loader picks up an empty pallet with a fork, brings it under a stack of pallets, hoists it, takes the stack to the steaming chamber and puts it in any convenient place.

Our Advantages

We work with big and medium-size companies of Russia, Kazakhstan, Ukraine, Belarus and other countries and always fulfill our obligations in time.

Shipping, customs control, documentation - we will advise you on all matters, as well as help you set up and configure the equipment

We have our own logistics system for delivery of products (vehicles, transport companies)

Due to our own production, our prices are lower than the market averages by 15-50%