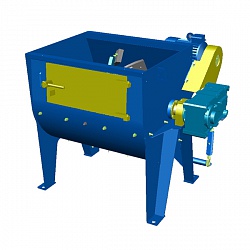

The features of "Weight batcher Rifey-Ves"

The batching system is a semi-automatic device with manual command issuing to start batching for each component.

The batching system connection does not imply introducing changes to the electrical installation of "Rifey-Buran" and "Rifey-Luch" lines.

The use of Rifey-Ves batchers allows to simultaneously batch a binding agent, water and an aggregate. The aggregate batcher is used for sequential multicomponent batching of up to three aggregate varieties. The basic configuration of "Rifey-Luch" and "Rifey-Buran" lines includes launch protection equipment, which allows controlling the binding agent feeding mechanism, as well as one mechanism for feeding the aggregate. Cement acts as a binding agent, while macadam production screenings, slags, sand, expanded clay, sawdust, ash and many other bulk materials can act as an aggregate; the said materials after mixing with the binding agent acquire and retain the shape set. The batching of water in most cases is done after mixing the aggregate and the binding agent.

The batching of both the aggregate and the cement is made by filling a certain batching tank, and subsequently - by unloading it. For unloading both the aggregate and the cement, the manual opening of certain dampers is done.

For batching, the required volume of water is drained from the batching tank, and then the volume of water is replenished. To replenish the volume of water, you must manually open a water tap.

The supply of both the cement and the aggregate is made by feeding mechanisms equipped with an electric drive. The water is supplied from the water supply network. The components are discharged directly into the mixer.

The batching of the components is carried out by means of the sets of batchers parameters, which are stored in the memory of the controller - formulas of the mix.

In the basic version, the batcher is adjusted at the manufacturing factory. The batcher is delivered assembled and ready for operation. If the customer has a technical ability to install the electronic part of the batching system, the latter is delivered to the consumer. In this case, the stages of both the electrical installation and adjustment of the batching system are carried out on the customer's areas.

Related products

Concrete Mixer SG-350 |

Our Advantages

We work with big and medium-size companies of Russia, Kazakhstan, Ukraine, Belarus and other countries and always fulfill our obligations in time.

Shipping, customs control, documentation - we will advise you on all matters, as well as help you set up and configure the equipment

We have our own logistics system for delivery of products (vehicles, transport companies)

Due to our own production, our prices are lower than the market averages by 15-50%