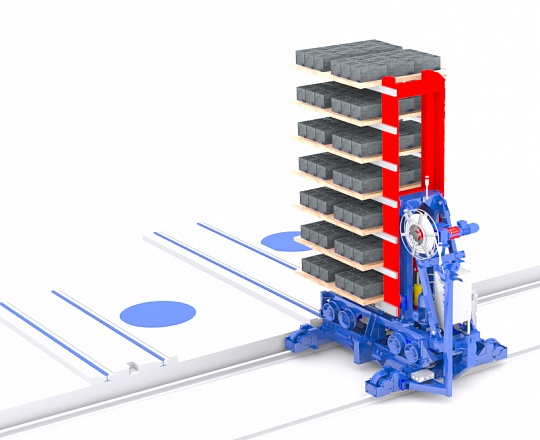

The trolley is transverse, moves along the rail tracks between the stackers and steaming chambers. It consists of the following main parts:

- Movable frame, driven by a gear motor through drive shafts to drive wheels. A part of the rails for the upper trolley is fixed on the frame;

- Contactless sensors for the trolley preliminary positioning relative to the fixed rail tracks (in steaming and stackers) and the initial position of the upper trolley;

- A mechanism for precise orientation and fixation of the lower trolley with a gear motor and contactless pushrod position sensors;

- An electrical cabinet with a controller, a frequency converter for controlling the drive, sensor cables, and other equipment;

- Movable frame, driven by a gear motor through drive shafts to drive wheels;

- Column with guides for hoisting and lowering of hoisting forks;

- Forks for holding pallets with products;

- Hydraulic system: a pumping unit and a hydraulic cylinder for hoisting forks; a system that determines the weight of products in order to limit the speed of a heavily loaded trolley;

- Cable drum with cable;

- Contactless sensors to position the fork trolley in steaming and stackers;

- Racks for fixing and tensioning the rope;

- Rope branch. Rope for cable with elements of fastening to racks;

- Carriage for fixing the cable and moving along the rope;

Allows wirelessly controlling all the mechanisms of the pallet transportation system in manual, semi-automatic and automatic mode. It is possible to upgrade to automatic mode. It consists of the following main parts:

- Control panel with controller, operator panel, joystick and control buttons. The joystick controls the movement speed of the trolleys in each of four directions;

- The control signal wireless transmission system from the controller of the control panel to the controllers of the transverse and fork trolley;

- A video surveillance system for remote control of trolleys (cameras, receiver and transmitter for wireless image transmission) allows displaying an image on the operator's monitor from four cameras mounted on a fork truck.

Our Advantages

We work with big and medium-size companies of Russia, Kazakhstan, Ukraine, Belarus and other countries and always fulfill our obligations in time.

Shipping, customs control, documentation - we will advise you on all matters, as well as help you set up and configure the equipment

We have our own logistics system for delivery of products (vehicles, transport companies)

Due to our own production, our prices are lower than the market averages by 15-50%