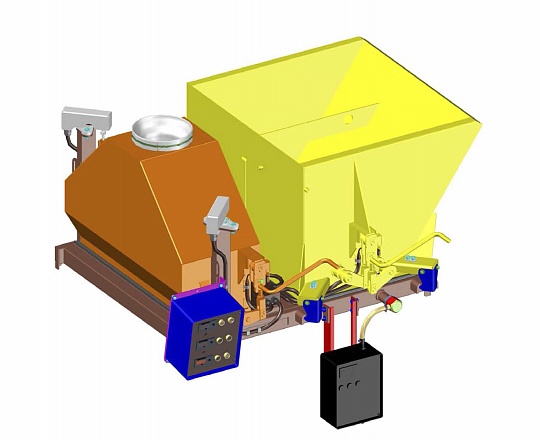

Features of the Rifey-Weight Weight Hopper

The dosing system is a semi-automatic device with manual commands to start dosing for each component.

The dosing system connection does not imply any changes to the electrical installation of the Rifey lines.

The use of Rifey-Ves hoppers allows dosing the binder, water and filler at the same time. Using a filler hopper, sequential multicomponent dosing of up to three varieties of filler is performed. The basic equipment of the Rifey lines includes start-up protection equipment that allows controlling the binder feed mechanism, as well as one filler feed mechanism. The binder role is performed by cement, and the filler role can be performed by screenings of crushed stone production, slags, sand, expanded clay, sawdust, ash and many other bulk materials, which acquire and retain a given shape after mixing with the binder ... Water dosing in most cases is carried out after mixing the filler and the binder.

The aggregate and cement are dozed by filling a certain dosing container, and subsequently - by its unloading. To unload the aggregate and cement, the manual opening of certain metering valves is performed.

For dosing, the required water volume is drained from the water supply system.

Cement and aggregate are supplied by feeding mechanisms equipped with an electric drive. Water is supplied from the water supply network. The components are discharged directly into the mixer.

The components are dozed using sets of hopper parameters that are stored in the controller's memory - mixture recipes.

In the basic version, the hopper is adjusted at the manufacturer. The hopper is delivered assembled and ready for operation. If the consumer has the technical capability to install the electronic part, the specified part of the dosing system is delivered to the consumer. At the same time, the stages of electrical installation and adjustment of the dosing system are carried out on the consumer's premises.

Our Advantages

We work with big and medium-size companies of Russia, Kazakhstan, Ukraine, Belarus and other countries and always fulfill our obligations in time.

Shipping, customs control, documentation - we will advise you on all matters, as well as help you set up and configure the equipment

We have our own logistics system for delivery of products (vehicles, transport companies)

Due to our own production, our prices are lower than the market averages by 15-50%