Manufacturing of Rifey and Кondor vibrating presses. Rifey Concrete plants

Official Website

- High-performance vibropress

- Mechanized vibropress

- Small-sized vibropress

- Concrete Plants

- Vibropress + Concrete

- Vibropress for FBS

- Component dosing systems

- Stacking and palletizing systems

- Concrete Mixers

- Conveyors

- Silos and Cement Bulk Storages

- Bins and Batchers

- Shape-generating molding tools

- Optional Equipment

- Spare Parts

Curb stone

Curbs (profile separators of roadway or lawn and sidewalk) are the construction material produced mostly by a (semi-dry) vibration compaction method. Almost any original raw material is suitable for manufacture:

- crushed stone;

- gravel;

- blast-furnace slag;

- sands;

- ash and slag mixtures;

- fly ash.

Cement is used as a binder. Standard length of vibro-compacted curbs is 1 meter. Three and six meter curbs (usually used for the fencing of tracks or highways) are made of reinforced concrete.

Advantages and use of curb

The main advantages of curb stones are high strength and frost resistance. These qualities are provided by the main raw material required for their manufacture that is the dense heavy concrete. The curbs made of cement-sand concrete have the best key figures. There is not only great frost resistance and strength, but also smooth surface that makes them visually appealing.

Curbs are widely used because they improve landscape. They are often used for finishing sidewalk paths, squares, courtyards, playgrounds, roads, parking lots and parking areas. In addition to aesthetics, curb significantly extends the life of the coating, preventing the breakup of the paving, the formation of cracks and the accumulation of water between the plates, the penetration of plants in a pedestrian zone. Separation of zones with curbs helps visual orientation of drivers and pedestrians, which largely prevents the occurrence of dangerous traffic situations.

The undoubted advantage of the curbs is a large number of colors. Depending on the qualities of the source material, one can get a durable building material of almost any color - from standard grey to complex colors, that efficiently mimic natural stones such as marble, granite and malachite. In the production process, the pigment is injected not only into the top layer, but throughout the depth. The resulting color does not fade for a lifetime.

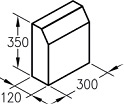

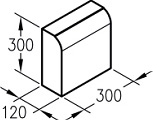

Curbs made of concrete are particularly relevant in cities where there are active works on improvement of the territory. Rifey Polus equipment can cope with the production of not only conventional rectangular curbs, but also roller ones. Curbs with beveled edges (lip curb) are particularly useful for improving access, parking zones, so as not to pose serious obstacles to car wheels.

The above-mentioned production of curbs can be carried out only by dry vibration compaction. Casting method in this case is ineffective, because the probability of damage to the product during manufacturing is too high. Moreover, the lifespan of the cast curb doesn’t exceed three years. If you want to get a really sound building material, it is necessary to use not just a method of vibration compaction, but the highest quality equipment. Needless to say, many large companies preferably use Rifey equipment for the manufacture of curbs that is able to provide excellent quality of the material and high performance.

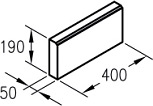

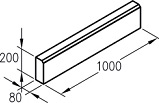

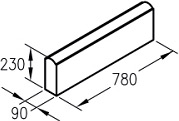

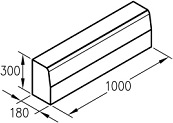

Types of curbs:

|

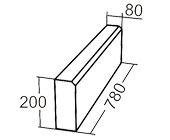

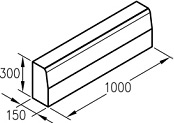

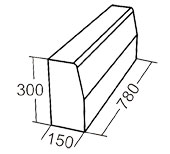

Curb stone BK-4

(Code: 614.5)

Equipment for the production

of curbs : |

||