Manufacturing of Rifey and Кondor vibrating presses. Rifey Concrete plants

Official Website

- High-performance vibropress

- Mechanized vibropress

- Small-sized vibropress

- Concrete Plants

- Vibropress + Concrete

- Vibropress for FBS

- Component dosing systems

- Stacking and palletizing systems

- Concrete Mixers

- Conveyors

- Silos and Cement Bulk Storages

- Bins and Batchers

- Shape-generating molding tools

- Optional Equipment

- Spare Parts

Wall stone

Today, wall stone almost forced out concrete slab of construction market. In the production of wall blocks haydite, cement, and water are used as a starting material. Haydite i.e. expanded and subsequently burnt clay, each granule of which is covered with a caked surface. That is why it guarantees a high level of grain strength. As a result, haydite is both durable and lightweight and acts as a perfect porous filler for producing wall blocks. If there is an enterprise producing sawdust waste (conifers), you can manufacture the wall stones from wood concrete. Disadvantages of manufacturing of wood concrete mixes include a significant deterioration in quality of the stone, if old sawdust is used or in case of disproportional ratio of water, binder and aggregate. Another available aggregate for wall stones is locally produced slag. Supporting walls require slag concrete of 35 and 50 grade. Partitions can be built of stones, manufactured from slag concrete of 25 grade. The ratio of large to small slag - 4 to 6.

A binder is as important as an aggregate. The following binders are usually used for wall blocks:

- cement binder;

- lime binder;

- slag binder;

- gypsum binder;

Profitability of wall blocks production

The applicability of this building material is explained by a combination of low weight with high strength, which allows to construct a low-rise building (maximum of three floors) without the use of complex lifting equipment. Savings are achieved not only due to the lack of expensive equipment. Brick laying requires small amount of grout, the size of the wall stone reaches a size of 8 bricks. Such stones are used both in the construction of supporting exterior walls and partition walls between rooms. Wall stones are used in monolithic concrete structures (frame filling). They are used for construction of cottages, garages, household outbuildings.

The use of wall stones in construction leads to an increase in usable space due to reduced wall thickness. When compared with a brick, using of stones greatly accelerates installation (usually, 4-5 times), it reduces the amount of the grout for more than a half (cubic meter of masonry is decreased by half). At the output, cost account (except for the cost of the material) is reduced by at least a third.Advantages of wall stone

Considerable advantages of the wall stone, along with the high speed of construction, is increased durability of a building and enhanced thermal insulation properties. The latter quality is achieved mainly due to the voids in the stones, which can be up to 30% of the total amount. If the voids occupy only a quarter of the total amount, then it is better to use such stones for the partition walls. However, if the external wall is planned to bear very small loads, then the use of stones with low hollowness is acceptable. Solid stones are recommended for semi-basements, walls of industrial buildings and utility rooms.

Nowadays, production of this building material is very profitable. Vibration compaction (volumetric semi-dry) is used for the production of stones. Best results are achieved with the help of Rifey line equipment: Kondor, Luch, Buran, and Universal models. These lines allow you to set up production of high-quality products at minimum costs.

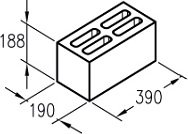

Types of wall stones

|

|

|

|

|

|

|

|

|

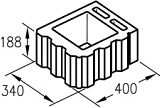

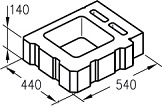

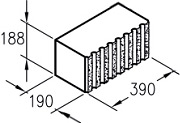

2-cavity corner wall stone with rough surface

(Code: 171)

Equipment :

|

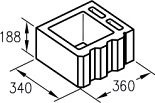

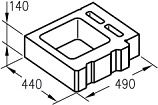

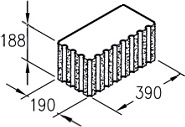

2-cavity course wall stone with rough surface

(Code: 172)

Equipment :

| |

|

|

|

|

|

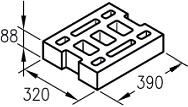

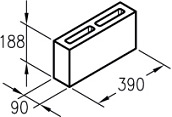

Partition stone 90mm

(Code: 109)

Equipment :

|

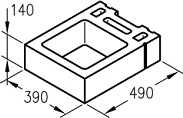

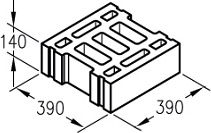

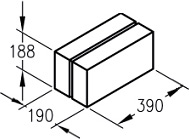

Solid wall block with a groove

(Code: 197)

Equipment :

| |

|

|

|

|

|

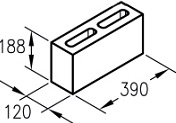

Partition stone 120mm

(Code: 108)

Equipment :

| ||

|

|

|

|

|

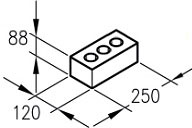

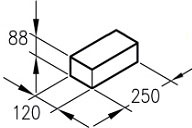

Thickened wall brick

(Code: 110)

Equipment :

|

Bevelled wall stone with slots

(Code: 130)

Equipment :

|

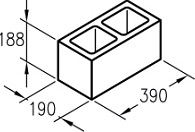

2-cavity wall stone

(Code: 158)

Equipment :

|

|

|

|

|

|

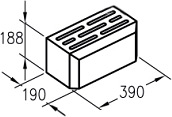

Wall stone with round cavities

(Code: 151)

Equipment :

|

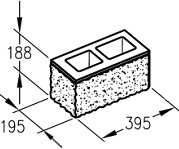

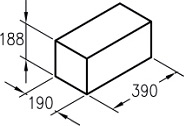

Solid wall stone SKts-1

(Code: 102)

Equipment :

|

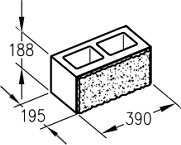

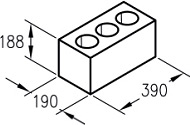

Hollow wall stone SKTs-1

(Code: 101)

Equipment :

|

|

|

|

|