Manufacturing of Rifey and Кondor vibrating presses. Rifey Concrete plants

Official Website

- High-performance vibropress

- Mechanized vibropress

- Small-sized vibropress

- Concrete Plants

- Vibropress + Concrete

- Vibropress for FBS

- Component dosing systems

- Stacking and palletizing systems

- Concrete Mixers

- Conveyors

- Silos and Cement Bulk Storages

- Bins and Batchers

- Shape-generating molding tools

- Optional Equipment

- Spare Parts

Wall blocks

Wall block is a structural building material, which is used for walls with few joints in the masonry. Wall blocks are subdivided into:

- concrete;

- foam concrete;

- polystyrene concrete;

- haydite concrete;

- gas silicate;

- gas concrete;

- tongue-and-groove.

The main components of foam concrete are cement, sand, water and foam. Gas silicate consists of quartz sand, cement, water, lime, and aluminum powder, which acts as a gas-forming agent. While foam concrete products can dry in a natural environment, gas silicate product require autoclave conditions (which is also used for preliminary foaming). Another popular material for the manufacturing of wall blocks is haydite concrete. Haydite concrete and gas silicate blocks have the following characteristics in common: light weight, high sound insulation and low thermal conductivity, they do not break down at high temperatures and do not burn. If you want to increase the insulation level of a block, then it should be manufactured from a mixture of cement and polystyrene. The cheapest material for the production of wall blocks is slag combined with crushed stone, gravel, sawdust, sand, granite. Besides the low price, slag blocks are characterized by sufficient durability. They are usually used for the construction of non-residential buildings, factory premises, and agricultural buildings. There are various types of materials, geometric shapes, and thickness of the wall blocks.

Profitability and application

Efficient use of the blocks in construction is associated with their large size and small cost of raw materials for their production. Thinner walls (but not more conductive) increase the amount of usable inner space. Similar brick buildings require a fivefold increase of the construction time; in addition, you will need much more masonry mortar. The total cost of the work using the building blocks is reduced by 40% compared to brick construction.

In reinforced concrete monolithic construction, frames are filled with wall blocks of different thickness. Wall block is suitable not only for load-bearing walls but also for partition walls. Possibility of manufacturing the products of different texture, size and coloring allows implementing many architectural projects. Many of the blocks successfully adjust humidity in premises, as they are breathable. This building material does not burn, does not rot, does not require repair for a long time (several decades).

Manufacturing of wall blocks

Wall blocks are manufactured with the help of brick making machines, as-molded products are subsequently cured. Sophisticated technology of Rifey lines, continuous quality control at all stages of the manufacturing process allow obtaining products with consistently high quality, stable strength characteristics. With Rifey equipment, it is possible to produce in a short time large quantities of blocks that meet the standards of Europe and Russia. Thus, we satisfy constantly growing customers demand for the building blocks.

Types of wall blocks:

|

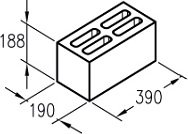

Hollow wall stone SKTs-1

(Code: 101)

Equipment :

|