Manufacturing of Rifey and Кondor vibrating presses. Rifey Concrete plants

Official Website

- High-performance vibropress

- Mechanized vibropress

- Small-sized vibropress

- Concrete Plants

- Vibropress + Concrete

- Vibropress for FBS

- Component dosing systems

- Stacking and palletizing systems

- Concrete Mixers

- Conveyors

- Silos and Cement Bulk Storages

- Bins and Batchers

- Shape-generating molding tools

- Optional Equipment

- Spare Parts

Paving slabs

One of the main features of any modern city is paving slabs. It is characterized by a great number of advantages that make it much more attractive than, for example, asphalt. The basic material for the manufacturing of paving slabs at the plants is concrete mix. It is poured into special molds, which make it possible to produce paving slabs of all sizes and shapes. Of course, you can vary colors of produced material by adding appropriate additives. It allows you to create the best suitable paving slab for a particular locality.

History of paving slabs

People began to pave roads with artificial stones not so long ago. A paving slab appeared only in the XIX century. Moreover, Dutch inventors used it once for paving the highway that connected Haarlem to Amsterdam

Use of paving slabs

- pedestrian precincts, squares, roads, parks, suburban areas;

- decoration of swimming pools;

- technological transport parking (parking aprons at the Hong Kong airport);

- cargo loading and unloading areas (marine container terminals in Hamburg and Baltimore);

- low-speed highways;

- outdoor storages, transshipment sites.

As the name implies, the main field of use of this material is the paving of sidewalks. In this field, it is practically impossible to find a more suitable material. One of its main advantages is its high durability. If you are using brick making machines to produce paving slabs, its operating life will last at least three decades. Small joints between the slabs allow rain and melt water to seep into the ground without forming puddles on the pavement. And, of course, at unusually high temperatures in the summer slabs do not melt like asphalt, which evolves volatile toxic substances that can harm human health. Thus, it is a clear material from an environmental point of view, the use of which is justified from either direction.

Laying of paving slabs

Properly laid paving slabs are easy to dismantle and to be laid again. If you urgently need to repair communications under the pavement, it is not necessary to purchase a new batch of slabs. You need only disassemble, carry out repair works and put the same slabs in place again.

While natural stone paving is still in use, advantages of artificial stone are undeniable. Clear shapes and same dimensions make the installation process easier and faster. A wide range of colors allows you to create an artistic, almost mosaic covering. Production of paving is low-cost and fast-payback. Finally, a variety of matrices and color pigments make it possible to obtain a full simulation of not only the natural stone but also wood.

One of the most popular brick making machines for the production of paving slabs is Rifey-Buran line equioment. Short production time, high performance and reliability – all these characteristics make this equipment so popular.

Types of paving slabs:

|

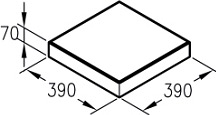

Paving slab 250х250

(Code: 447)

Equipment for the production of paving slabs:

|

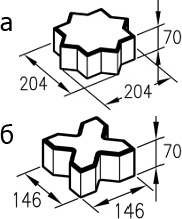

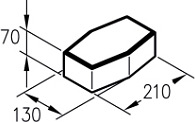

Paving slab "Prolonged hexagon"

(Code: 421)  |

|

|

|

|

|

|

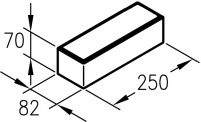

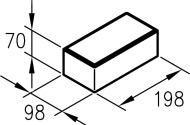

Paving slab "Rectangular 250x82"

(Code: 449)

Equipment :

|

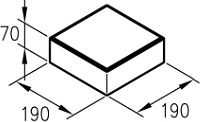

Paving slab "Square 19"

(Code: 411)

Equipment :

|

Paving slab 100х200

(Code: 430)

Equipment :

|

|

|

|

|

|

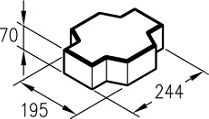

Paving slab "Wave"

(Code: 419)

Equipment :

|

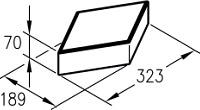

Paving slab 1F9.7 "Broad"

(Code: 405)

Equipment :

|

|

|

|

|

|

|

Paving slab PT R 33-19 "Rhomb"

(Code: 407)

Equipment :

|

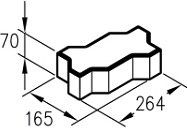

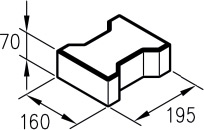

Paving slab PT K 19-16 "Bobbin"

(Code: 403)

Equipment :

|

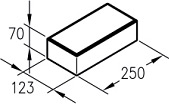

Paving slab PT P 25-12 "Rectangular 250х123"

(Code: 402)

Equipment :

|

|

|

|

|

|

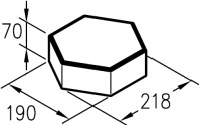

Paving slab PT Sh 22-19 "Hexagon"

(Code: 401)

Equipment :

|

|

|