Manufacturing of Rifey and Кondor vibrating presses. Rifey Concrete plants

Official Website

- High-performance vibropress

- Mechanized vibropress

- Small-sized vibropress

- Concrete Plants

- Vibropress + Concrete

- Vibropress for FBS

- Component dosing systems

- Stacking and palletizing systems

- Concrete Mixers

- Conveyors

- Silos and Cement Bulk Storages

- Bins and Batchers

- Shape-generating molding tools

- Optional Equipment

- Spare Parts

Haydite concrete wall blocks (haydite blocks)

The production of haydite blocks uses such fill materials as haydite (granular clay), cement and water. The main advantage of these blocks is high sound and heat insulation, which allows using this material in the construction of residential and industrial facilities. There is another important fact that haydite blocks are high resistant to various corrosive materials. The use of coarse aggregate enables to significantly reduce the total weight of the constructed structure.

Haydite blocks are used for different construction purposes: for placing interior partitions, load-bearing walls or outer walls in facilities of different assignment. They are often used in frame filling, if there is a monolithic ferroconcrete housing construction, and in the construction of various agricultural buildings, cottages, sheds, workshops and garages.

In contrast to other building materials, another property of haydite concrete is its ability to breathe, the porosity, making the adjustment of humidity in the spaces controlled. Thus the material is not subject to burning or rotting, which sets haydite block apart from wood. Compared to metals, haydite block doesn’t rust. But it adopted the reliability and durability of metal together with light weight and excellent thermal insulation of wood. All this makes this material the best choice for use in the construction of any buildings in different climatic conditions.Features of haydite blocks

- simple two-component composition of aggregate;

- small volume weight (pressure on the foundation is reduced);

- high sound insulation (better than lightweight concrete);

- high thermal insulation (better than normal concrete);

- high strength (competent production of haydite concrete in conjunction with proper design allow the construction of up to 12 floors; due to the presence of through voids in the product, it is possible to mount a hidden frame in the wall body, which enhances carrying capacity; however, such blocks are not recommended for foundation and plinth);

- high moisture resistance (better than cement concrete);

- high chemical resistance to solutions of sulfates, carbon dioxides, caustic alkalis, soft water (better than cement concrete);

- heat resistance exceeds 1000C;

- air permeability (transpirable material facilitates the creation of a controlled indoor environment, eliminating the dew point);

- ecological cleanliness (mix is composed of natural materials, the composition of which is close to the brick one, haydite block is suitable for construction in different latitudes);

- practical structural properties (application in load-bearing structures, easy machinability);

- low cost (cheaper than normal concrete, bricks).

Those who consider haydite blocks novices at the domestic construction markets are wrong. In Soviet times, this material had been successfully used by builders for decades but could not get wide distribution because of the high cost of production. Everything has changed in our days with the appearance of Rifey brick making machines.

Rifey equipment allows establishing large-scale production of haydite blocks in a short time. But the quality of the material is notable for the improved performance that makes these lines particularly attractive for many companies.

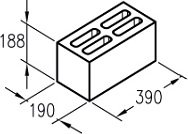

Manufactured haydite blocks:

|

Arbolit blocks

|

Hollow wall stone SKTs-1

(Code: 101)

Equipment for the production of haydite blocks:

|